There are several issue’s pertaining to the Paducah Gaseous Diffusion Plant and it’s cleanup. The story immediately below appeared on April 5th.

Reporter – Jason Hibbs

Photojournalist – Mason Watkins

MCCRACKEN COUNTY, Ky. — People can’t see it, taste it or even smell it but they know it’s underground, and it can be deadly.

That’s why neighbors of the Paducah Gaseous Diffusion Plant are relieved to hear the Department of Energy, the Environmental Protection Agency and the Kentucky Department of Environmental protection are set to start a major decontamination project to remove that contamination from the soil.

It’s a cancer-causing chemical known as trichloroethene. It’s used in products like automotive brake cleaner, printer toner enhancer and film cleaner.

But from 1950 to 1993, TCE was used as a degreaser at the Paducah Gaseous Diffusion Plant. Now the hazardous substance is in the aquifer. It will take 18 million dollars to start cleaning it up.

"My family’s owned the property since something like 1950 and just had a well," Fay Buckingham said.

Fay and Ray Buckingham drank the well water until someone from the DOE told them to stop. The government installed city water and has paid the Buckinghams water bill ever since, but the two doubt the DOE even cares.

"They got more dad-gumb degrees than a thermometer but that don’t make them good people," Fay said.

But Ralph Young, a retired environmental engineer and now chair of the Citizens Advisory Board to the DOE, said the $18 million cleanup project is a responsible move, not just environmentally but economically, because someday, the plant will close.

"For future re-industrialization of site and future use of the land, it’s really important to clean it up," Young said.

Right now, just beneath the plant, sits a highly-concentrated area of TCE and downstream in the aquifer are less concentrated amounts of the same substance in what the Energy Department calls plumes.

Young said the department started clean up at the northwest and northeast plumes because they didn’t want the T.C.E. to spread out here, even toward the Ohio River. Now that cleanup here is under way, they’ll go to the source, with the highest concentration of T.C.E. below the plant. CONTINUE READING…

Continuing on with the story published on the Kentucky Hemp Coalition’s site:

PADUCAH, Ky. (AP) — Federal and state agencies are set to begin removing contaminated soil from around the Paducah Gaseous Diffusion Plant in an $18 million project designed to clean up four decades of pollution.

The U.S. Department of Energy, the Environmental Protection Agency and the Kentucky Department of Environmental Protection want to remove the cancer-causing chemical trichloroethene. The chemical, also called TCE, is used in automotive brake cleaners and printer tone enhancers and was used as a degreaser at the plant. Officials say it leaked into the aquifer beneath the facility.

Neighbors say they were sickened by the contamination. Fay and Ray Buckingham drank the well water until someone from the DOE told them to stop. The government installed city water and has paid the Buckinghams water bill ever since, but the two are doubtful that the Energy Department even cares.

"They got more dad-gumb degrees than a thermometer but that don’t make them good people," Fay Buckingham told WPSD-TV in Paducah (http://bit.ly/HUU5og ).

Ralph Young, a retired environmental engineer and now chair of the Citizens Advisory Board to the Department of Energy, said the cleanup is a responsible move, not just environmentally but economically, because someday, the plant will close.

"For future re-industrialization of site and future use of the land, it’s really important to clean it up," Young said.

The project is set to start no later than June 2013. CONTINUE READING…

And still yet there is more to be learned from this story…

Paducah Gaseous Diffusion Plant – Wikipedia

The former Kentucky Ordnance Works site was chosen from a candidate list of eight sites in 1950. The construction contractor was F.H. McGraw of Hartford, Connecticut, and the operating company was Union Carbide. The plant was opened in 1952 as a government-owned, contractor-operated facility, producing enriched uranium to fuel military reactors and for use in nuclear weapons. The mode of enrichment was the gaseous diffusion of uranium hexaflouride to separate the lighter fissile isotope, U-235, from the heavier non-fissile isotope, U-238. The Paducah plant originally produced low-enriched uranium, which was further refined at Portsmouth and the K-25 plant at Oak Ridge, Tennessee. From the 1960s the Portsmouth and Paducah plants were dedicated to uranium enrichment for nuclear power plants. In 1984 the operating contract was assumed by Martin Marietta Energy Systems. Lockheed Martin has operated the plant since the merger of Martin Marietta with Lockheed in 1995. From 2001, all USEC production has been consolidated at Paducah.[2][3]

The Paducah plant had a capacity of 11.3 million separative work units per yar (SWU/year) in 1984. 1812 stages were located in five buildings: C-310 with 60 stages, C-331 with 400 stages, C-333 with 480 stages, C-335 with 400 stages and C-337 with 472 stages.

CONTINUING ON….

Weapons of Mass Destruction (WMD)

Gas Centrifuge Uranium Enrichment

A method in widespread use is the gas centrifuge [Urenco (Netherlands, Germany, UK), Russia, Japan] in which UF6 [Uranium Hexafluoride]gas is whirled inside complex rotor assemblies and centrifugal force pushes molecules containing the heavier isotope to the outside. Again, many stages are needed to produce the highly enriched uranium needed for a weapon, but centrifuge enrichment requires much less electricity than either of the older technologies.

The use of centrifugal fields for isotope separation was first suggested in 1919; but efforts in this direction were unsuccessful until 1934, when J.W. Beams and co-workers at the University of Virginia applied a vacuum ultracentrifuge to the separation of chlorine isotopes. Although abandoned midway through the Manhattan Project, the gas centrifuge uranium-enrichment process has been highly developed and used to produce both HEU and LEU. It is likely to be the preferred technology of the future due to its relatively low-energy consumption, short equilibrium time, and modular design features. CONTINUE READING…

From the original (AP) article…

a spokesperson with LATA, the company in charge of the decontamination, said there are actually seven sources of T.C.E. all within the same area. This $18 million project pays for the decontamination of the three most significant sources, so that still leaves four remaining sources that need to be decontaminated.

Nuclear

LATA provides project management, facility operations and maintenance, remediation, D&D, waste management, and project services…

Environmental

LATA provides comprehensive environmental services from assessment and investigation through site remediation and remedial system design/construction to operation and long-term site management…

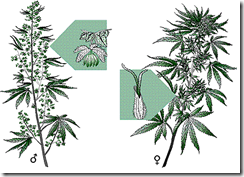

Using HEMP to help restore the land in Chernobyl

In 1998, Phytotech, along with Consolidated Growers and Processors (CGP) and the Ukraine’s Institute of Bast Crops, planted industrial hemp, Cannabis sp., for the purpose of removing contaminants near the Chernobyl site. Cannabis is in the Cannabidaceae family and is valuable for its fiber, which is used in ropes and other products. This industrial variety of hemp, incidentally, has only trace amounts of THC, the chemical that produces the "high" in a plant of the same genus commonly known as marijuana. CONTINUE READING FURTHER INFORMATION…

Now, according to the statement below, they are set to begin “MOVING” the contamination…..My question is where are they moving it to and why not try using hemp and other natural plants as outlaid in the story above to clean up this mess. There has to be an immediate danger when moving this type of material. Not to mention the $18 million dollar price tag for LATA.

Hemp "Eats" Chernobyl Waste, Offers Hope For Hanford

by Elaine Charkowski

Central Oregon Green Pages

An explosion at a nuclear reactor on April 26th, 1986 in Chernobyl, Ukraine created the world’s worst nuclear disaster – so far.

The blast heavily contaminated agricultural lands in a 30 km radius around the reactor. The few people still living there must monitor their food and water for radiation. However the combination of a new technology (phytoremediation) and an old crop (industrial hemp) may offer the Ukraine a way to decontaminate it’s radioactive soil.

In 1998, Consolidated Growers and Processors (CGP), PHYTOTECH, and the Ukraine’s Institute of Bast Crops began what may be one of the most important projects in history – the planting of industrial hemp for the removal of contaminants in the soil near Chernobyl.

CGP is an ecologically-minded multinational corporation which finances the growing and processing of sustainable industrial crops such as flax, kenaf, and industrial hemp. CGP operates in North America, Europe and the Ukraine.

PHYTOTECH (see webpage: www.phytotech.com/index.html ) specializes in phytoremediation, the general term for using phyto (plants) to remediate (clean up) polluted sites. Phytoremediation can be used to remove radioactive elements from soil and water at former weapons producing facilaties. It can also be used to clean up metals, pesticides, solvents, explosives, crude oil, polyaromatic hydrocarbons, and toxins leaching from landfills.

Plants break down or degrade organic pollutants and stabilize metal contaminants by acting as filters or traps. PHYTOTECH is conducting feild trials to improve the phytoextraction of lead, uranium, cesium-137, and strontium-90 from soils and also from water.

Founded in 1931, the Institute of Bast Crops is now the leading research institution in the Ukraine working on seed-breeding, seed-growing, cultivating, harvesting and processing hemp and flax.

The Bast Institute has a genetic bank including 400 varieties of hemp from various regions of the world.

"Hemp is proving to be one of the best phyto-remediative plants we have been able to find," said Slavik Dushenkov, a research scienst with PHYTOTECH. Test results have been promising and CGP, PHYOTECH and the Bast Institute plan full scale trials in the Chernobyl region in the spring of 1999.

Industrial hemp is not a drug. Unlike its cousin marijuana, industrial hemp has only trace amounts of THC – the chemical that produces the high. In 1973, the Department of the Interior and Department of Health and Agriculture of the former USSR issued an ultimatim to the Institute of Bast Crops – either create non-psycoactive varities of hemp or stop cultivating hemp. So, scientists at the institute created an industrial hemp plant containing only minute traces of THC. Modern testing in Canada confirmed the low THC content of the Bast Institute’s hemp.

New technologies in hemp harvesting and processing are also being developed at the Institute whose library contains more than 55,000 volumes mainly on hemp-growing and flax-growing.

Chernobyl may seem distant, but the EPA estimates that there are more than 30,000 sites requiring hazardous waste treatment throughout the U.S. including Hanford and Three Mile Island.

Phytoremediation with industrial hemp could be used at many of these sites. Unfortunantly, the U.S. government refuses to legalize the cultivation of industrial hemp and clings to the obsolete myth that it is a drug.

CONSOLIDATED GROWERS AND PROCESSORS, INCORPORATED

ITEM 1. DESCRIPTION OF BUSINESS

Consolidated Growers and Processors, Incorporated (hereinafter "CGP" or "the Company"), OTC BB: CGPR, was formed and incorporated in Delaware on June 10, 1997 for the principal purpose of engaging in the large scale commercialization of alternative industrial crop products, primarily industrial hemp, through the development and / or acquisition of new and advanced technologies. The Company was funded through a Reg 504D offering and listed on the OTC market as of October 27, 1997. In October 1997, the Company acquired a minority interest in a German company, Badische Naturfaseraufbereitung ("BaFa"). In 1998, the Company furthered its international operations through the formation of its wholly-owned Canadian subsidiary, Consolidated Growers and Processors (CGP) Canada Limited ("CGP Canada"), NAWARO GmbH ("NAWARO") in Germany and CGP Europe AG ("CGP Europe")in Switzerland. In June 1998, the Company also acquired a 100% interest in a Swiss corporation, Werner Zoellig AG & Glulam Lumber Mfg. ("Zoellig"). The Company has subsequently restructured its European holdings:

it has increased its investment in BaFa from 15 percent to 75 percent (effective July 1, 1999) and has sold Zoellig to focus on its core business, the agriculture and processing of industrial hemp. At present, the Company employs nine people.

CGP has created an integrated, global strategy to become the lowest cost producer and preeminent supplier of industrial hemp raw material products, and certain value-added products, in key market segments such as:

a) Nutraceuticals from hemp plant compounds (nutraceuticals are natural compounds that provide health or medicinal benefits beyond basic nutritional needs for disease prevention and / or health maintenance);

b) Pharmaceuticals produced from hemp plant compounds (pharmaceuticals are medical drug products);

c) Hemp food products with nutritional advantages;

d) High quality hemp fibers for production of biocomposites (a biodegradable composite of materials) and substitution of toxic petrochemical and synthetic products such as certain rubbers, plastics and fiberglass; and

e) Other environmentally friendly products such as "tree-free" paper made from hemp pulp. (Pulp is a material produced from the plant stem reduced to a soft uniform mass for making paper).

Cannabis can clean up Nuclear WASTE and MORE!

By Dion Markgraaff

The March earthquake in Japan and the resulting nuclear power plant disaster at Fukushima has rocked the entire world with the threat and spread of nuclear waste contamination. An unknown amount of different hazardous chemicals have been released into the atmosphere and ocean that threaten our food chain for the long foreseeable future. Hemp may be the key to reducing this damage we all face.

Many people know the cannabis plant has amazing healing powers, but it’s incredible that this same plant can literally “eat away” nuclear waste. As a cannabis plant enthusiast, it’s hard not to be overwhelmed by the many unbelievable uses of hemp. From the flower’s ability to aid and keep people from going blind, to the woody core of the stem’s ability to build fire proof homes and much more. Now, we can add another use to the list: Hemp as a tool to clean up nuclear contamination around Chernobyl. CONTINUE READING…

Now, my next question is why are we not calling on CGP vs. LATA and/or both, in order to get a true picture of what has actually happened in Paducah, and let the best idea and lowest cost analysis take the contract. Personally, I would really like to see CGP in there before anything is started…

CHERNOBYL NUCLEAR DISASTER PICTURES

FUKUSHIMA NUCLEAR DISASTER PICTURES

THREE MILE ISLAND NUCLEAR DISASTER PICTURES

PADUCAH GASEOUS DIFFUSION PLANT, KENTUCKY

IN ADDITION TO THE PADUCAH ISSUE WE ALSO HAVE THE BLUEGRASS ARMY DEPOT NUCLEAR ISSUE…

The Blue Grass Army Depot (BGAD) is one of nine Army installations in the United States and currently stores chemical weapons. Located near Richmond, Ky., BGAD, a subordinate installation of the Joint Munitions Command, encompasses approximately 14,600 acres, comprised mainly of open fields and wooded areas. The depot is primarily involved with industrial and related activities associated with the storage and maintenance of conventional and chemical munitions.

The Blue Grass Chemical Activity (BGCA), a tenant organization of the depot that reports to the U.S. Army Chemical Materials Agency (CMA), is responsible for the safe, secure storage of the chemical weapons stockpile stored at the depot, which comprises 523 tons of nerve agents GB and VX, and mustard agent in projectiles, warheads and rockets.

The U.S. Army Element, Assembled Chemical Weapons Alternatives, known as ACWA, is the Department of Defense program responsible for the destruction of chemical weapons in Kentucky. Working in partnership with the community, the technology known as neutralization followed by supercritical water oxidation (SCWO) was selected in 2003 to destroy the chemical weapons stockpile.

Bechtel Parsons Blue Grass is the systems contractor that will design, construct, systemize, pilot test, operate and close the Blue Grass Chemical Agent-Destruction Pilot Plant.

Safety and Security

The safety of workers, the public and the environment are paramount to the success of the chemical weapons disposal mission. The U.S. Army Chemical Materials Agency (CMA) oversees the secure storage of chemical munitions to ensure that they are safe.

BGAD and BGCA are committed to the safe and secure storage of the chemical weapons until the stockpile can be eliminated.

Public Participation and Community Relations

The Kentucky Chemical Demilitarization Citizens’ Advisory Commission serves as a forum for exchanging information about the chemical weapons destruction project and represents community and state interests to the Army and Department of Defense, to ensure that the public is fully informed about the program.

The Chemical Stockpile Emergency Preparedness Program works closely with your community and state emergency professionals to develop emergency plans and provide chemical accident response equipment and warning systems.

To learn more about the Army’s chemical weapons disposal mission visit the Blue Grass Chemical Stockpile Outreach Office.

Monitors Detect Mustard Vapor Leak [83KB pdf] 3/12/2012 Blue Grass , KY – Army officials report a Real Time Analytical Platform, a mobile monitoring laboratory, detected low levels of Mustard agent vapor in a chemical weapons igloo containing 155 mm projectiles this morning.

BGCA Bi-Weekly Update – March 12, 2012 [270KB pdf] 3/12/2012 Blue Grass , KY – “All of you showed true patriotism by providing cards and notes of support to Wounded Warriors” stated Lt. Col. Steven Basso during an award presentation Feb. 8, to two first grade classes at Kit Carson Elementary School.

BGCA Bi-Weekly Update – February 20, 2012 [265KB pdf] 2/20/2012 Blue Grass , MD – Blue Grass Chemical Activity’s (BGCA) primary mission and focus is to ensure the safe and secure storage of “The Nation’s chemical weapons stockpile until elimination.”

BGCA Bi-Weekly Update – January 19, 2012 [308KB pdf] 1/19/2012 Blue Grass , MD – Blue Grass Chemical Agent-Destruction Pilot Plant (BGCAPP) Site Project Manager, Jeff Brubaker, hosted the first of three tours for employees of the Blue Grass Chemical Activity (BGCA) Thursday, Jan. 12.

![]()

![]()

Japan earthquake: Japan warned over nuclear plants, WikiLeaks cables show

Japan was warned more than two years ago by the international nuclear watchdog that its nuclear power plants were not capable of withstanding powerful earthquakes, leaked diplomatic cables reveal.

Evacuees are screened for radiation contamination at a testing center in Koriyama City, Fukushima Prefecture Photo: AP

By Steven Swinford, and Christopher Hope

9:30PM GMT 15 Mar 2011

An official from the International Atomic Energy Agency (IAEA) said in December 2008 that safety rules were out of date and strong earthquakes would pose a "serious problem" for nuclear power stations.

The Japanese government pledged to upgrade safety at all of its nuclear plants, but will now face inevitable questions over whether it did enough.

While it responded to the warnings by building an emergency response centre at the Fukushima plant, it was only designed to withstand magnitude 7.0 tremors. Friday’s devastating earthquake was a magnitude 9.0 shock.

The news is likely to put further pressure on Japan’s Prime Minister, Naoto Kan, who has been criticised for "dithering" over the country’s response to the ongoing crisis at the Fukushima nuclear power plant.

Panic started to spread throughout Japan yesterday following the news that a third explosion at the plant might have damaged the protective casing around the reactor core, increasing the threat of radioactive leaks.

Related Articles

-

Leading physicist calls China’s nuclear programme ‘rash and unsafe’

01 Jun 2011

-

Read the Wikileaks cables in full

15 Mar 2011

-

Pictures: before and after shots reveal tsunami devastation

16 Mar 2011

-

30 powerful images of the disaster

16 Mar 2011

-

Images of the stricken nuclear reactor

16 Mar 2011

-

LOCAL COURT ORDERS SHUTDOWN OF NUCLEAR REACTOR

15 Mar 2011

The government was considering using helicopters to spray water over the Fukushima site to limit the spread of radioactive particles as part of its increasingly desperate attempts to keep the situation under control.

Meanwhile the FTSE-100 share index fell by 1.4 per cent as stock markets around the world slumped in response to a 10.6 per cent drop in Japan’s Nikkei index.

Warnings about the safety of nuclear power plants in Japan, one of the most seismologically active countries in the world, were raised during a meeting of the G8′s Nuclear Safety and Security Group in Tokyo in 2008.

A US embassy cable obtained by the WikiLeaks website and seen by The Daily Telegraph quoted an unnamed expert who expressed concern that guidance on how to protect nuclear power stations from earthquakes had only been updated three times in the past 35 years.

The document states: "He [the IAEA official] explained that safety guides for seismic safety have only been revised three times in the last 35 years and that the IAEA is now re-examining them.

"Also, the presenter noted recent earthquakes in some cases have exceeded the design basis for some nuclear plants, and that this is a serious problem that is now driving seismic safety work."

The cables also disclose how the Japanese government opposed a court order to shut down another nuclear power plant in western Japan because of concerns it could not withstand powerful earthquakes.

The court ruled that there was a possibility local people might be exposed to radiation if there was an accident at the plant, which was built to out of date specifications and only to withstand a "6.5 magnitude" earthquake. Last Friday’s earthquake, 81 miles off the shore of Japan, was a magnitude 9.0 tremor.

However, a cable from March 2006 reported that the court’s concerns were not shared by the country’s nuclear safety agency.

It says: "Japan’s Nuclear and Industrial Safety Agency believes the reactor is safe and that all safety analyses were appropriately conducted."

The Government successfully overturned the ruling in 2009.

Another cable reported to Washington local concerns that a new generation of Japanese power stations that recycle nuclear fuel were jeopardising safety.

The cable, quoting a local newspaper, reports: "There is something precarious about the way all electric power companies are falling in step with each other under the banner of the national policy. We have seen too many cases of cost reduction competition through heightened efficiency jeopardizing safety."

The cables also disclose how Taro Kono, a high-profile member of Japan’s lower house, told US diplomats in October 2008 that the government was "covering up" nuclear accidents.

He alleged that the government was ignoring alternative forms of energy, such as wind power.

The cable states: "He also accused METI [the Ministry of Economy, Trade, and Industry] of covering up nuclear accidents, and obscuring the true costs and problems associated with the nuclear industry." He added that the Japan’s "extensive seismic" activity raised safety concerns about storing nuclear material.

Mr Kan was not in office at the time the nuclear warnings were made. He became science and technology minister in 2009 and prime minister in June 2010.

In closing, I would like to say that with all the nuclear “garbage” we have strung out all over the world we had better come up with something very useful in cleaning these messes up fast. It could mean our very lives – and has costed many lives already. ShereeKrider

Leave a Reply